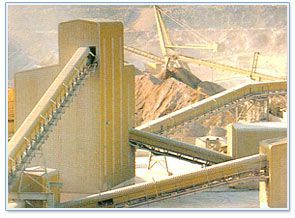

One that conveys, largely automated mechanism that transports materials, packages, or items being assembled from one place to another. The conveyors are particularly useful in applications involving the transportation of heavy or bulky materials.

Belt Conveyor:-

Belt conveyor works on the principle of resistance transmitting.

Features:

1. large conveying capacity.

2. Noise Reduction.

3. Simple structure.

4. Easy maintenance.

5. Energy-Saving and Low Cost.

6. Operate-temperature range from -20 degree to +40 degree.

7. Used to convey bulk materials like in mine, metallurgy, coal, traffic, water and electricity, etc.

Screw conveyors:-

Screw conveyor have been a popular material handling machinery.

Features:

1. Used horizontally or at a slight incline.

2. Efficient way of conveying.

3. Used to move semi-solid materials.

4. Consist of trough.

5. Trough contain:

> Spiral turn around a shaft, driven at one side and held at the other.

or

> Shiftless spiral ,driven at one side and free at the other.

6.Ease of Cleaning.

7.Less maintenance.

Pan conveyors:-

Pan conveyors are used to handle hot clinkers with a Temperature of 80 to 120 Degree Celsius. These used for vibrating feeder carrying of clinker from the one location to other location.

1.High tensile strength and flawless performance.

2.Highly reliable.

3.Anti corrosive.

4.Fine finish.

Chain Conveyors:-

The chain conveyor are suitable for bulk material transfer. Chain conveyor is commonly used in most of industrial field for their product packaging. The main Characteristic of Powered Roller Conveyor is it stronger where heavier products are being handled.

Chain conveyor is used in parallel bulk material conveying for abrasive and hot material.

A Pneumatic conveyor:-

Pneumatic conveyor is exclusive and useful pneumatic conveyor conveying equipment that is needed for conveying the powders vertically at heights that vary from low levels to as high as Maximum. Its depending upon the capacity of equipment.

Features:

1.No moving parts

2.No maintenance

3.Low power consumption.

Due to this feature, it is highly demanded in the domestic as well as international market & it can be customized as per the specifications.

Roller conveyers:-

Roller conveyor which is highly appreciated for international level of quality. The roller conveyor is also use for in house transport, Flexible & user friendly system for most of industries like packaging, conveying etc.